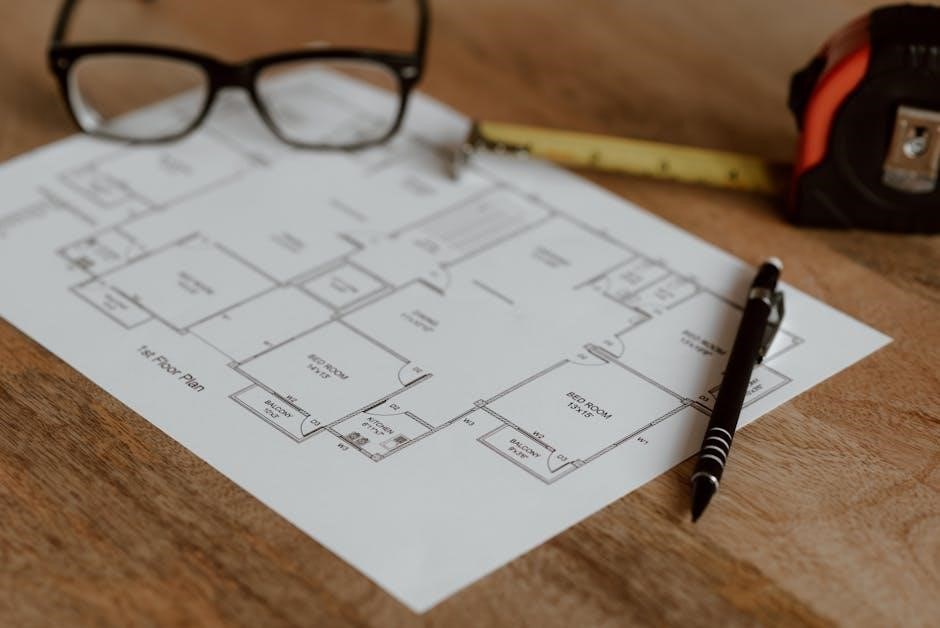

MTD 46 Inch Deck Belt Diagram: A Comprehensive Guide

Navigating the intricacies of a manual MTD 46-inch deck belt diagram is crucial for proper maintenance and repair, ensuring optimal lawn care performance.

Understanding the MTD 46-Inch Deck

The MTD 46-inch deck, commonly found on various lawn tractors and zero-turn mowers, represents a standard size offering a balance between maneuverability and cutting efficiency. Understanding its construction is vital for successful belt replacement. This deck typically features a stamped steel construction, providing durability while keeping weight manageable. Key components include the deck shell itself, three spindle assemblies housing the blades, an idler pulley system for belt tensioning, and various support brackets.

The deck’s design facilitates a consistent cut quality across a wide swath. Proper alignment of these components is essential; misalignment can lead to premature belt wear or uneven cutting. Many MTD 46-inch decks are compatible with Husqvarna models, sharing similar designs and parts. Accessing detailed diagrams, often found in owner’s manuals or online parts lookups, is paramount for identifying each component and understanding its function within the overall system.

Belt Diagram Importance

A manual MTD 46-inch deck belt diagram is absolutely essential for correctly routing the drive belt, ensuring proper functionality of the mowing deck. Incorrect belt routing can lead to belt slippage, inefficient cutting, and potential damage to the spindle assemblies or idler pulleys. The diagram visually illustrates the precise path the belt must follow around each component – spindles, idlers, and the deck itself.

Without a diagram, reassembly becomes a guessing game, increasing the risk of errors. Diagrams also aid in identifying the correct belt size and type for your specific model. Furthermore, understanding the diagram helps diagnose belt-related issues, such as slippage or premature wear, by pinpointing potential problem areas within the system. Accessing a clear, accurate diagram is the first step towards successful belt maintenance and repair.

Identifying Your MTD Model

Accurately identifying your specific MTD 46-inch deck model is paramount before attempting any belt replacement or referencing a diagram. MTD manufactures equipment under various brands – Cub Cadet, Yard Machines, and Husqvarna – and even within these brands, numerous sub-models exist. The correct belt diagram varies depending on the exact model year and configuration.

Locate the model and serial number, typically found on a decal affixed to the mower’s deck or frame. This information is crucial when using online MTD parts lookup tools or consulting owner’s manuals. Incorrect model identification will result in an inaccurate diagram and potentially the wrong belt size, leading to improper operation and further issues. Double-check the model number to ensure compatibility before proceeding with any repairs or maintenance;

Belt Types and Specifications

Understanding belt specifications – size (1/2 x 91.4) and material – is vital for selecting the correct replacement belt for your MTD 46-inch deck.

Common Belt Sizes for 46-Inch Decks

Determining the correct belt size is paramount when servicing an MTD 46-inch deck. Commonly, these decks utilize a 1/2 inch by 91.4 inch belt, often referenced as a replacement for MTD/Cub Cadet part numbers 754-04142 and 954-04142.

However, compatibility extends to belts specified for Husqvarna models like the Z4822 and Z4824, frequently employing a 5/8 inch by 53.9109243 inch belt for 48-inch decks.

It’s crucial to verify the exact size needed based on your specific model, as variations exist. Always cross-reference part numbers and consult diagrams to ensure a precise fit, preventing slippage or damage.

Incorrect sizing can lead to premature wear and reduced cutting performance.

Belt Material and Durability

MTD 46-inch deck belts are typically constructed from reinforced rubber compounds, designed to withstand the rigorous demands of lawn care. The durability of a belt hinges on its material composition and construction, influencing its resistance to stretching, cracking, and wear.

Higher-quality belts often feature aramid fiber reinforcement for enhanced strength and longevity, crucial for handling the torque generated by the engine and spindles.

Factors like operating conditions – exposure to heat, debris, and moisture – significantly impact belt lifespan.

Regular inspection and replacement, based on usage, are vital for maintaining optimal cutting performance and preventing unexpected failures.

Understanding Belt Part Numbers (e.g., 754-04142, 954-04142)

MTD belt part numbers, such as 754-04142 and 954-04142, are crucial for ensuring correct replacement. These numbers aren’t merely identifiers; they encode specific belt dimensions, material specifications, and compatibility information for various MTD models.

The initial digits often indicate the manufacturer or a specific product line, while subsequent numbers detail the belt’s size and construction.

Cross-referencing these numbers is essential, as a single deck size can accommodate multiple belt numbers depending on the manufacturing year or specific model variation.

Always verify the part number against your owner’s manual or the original belt before ordering a replacement to avoid compatibility issues.

Locating the Belt Diagram

Finding the correct belt diagram involves utilizing MTD’s online parts lookup tools, Husqvarna diagrams (due to compatibility), and referencing your owner’s manual.

MTD Parts Lookup Tools Online

MTD offers a robust online parts lookup system directly on their website, allowing users to pinpoint diagrams specific to their mower model. This invaluable resource requires the model and serial number, typically found on a decal affixed to the mower’s deck or frame. Inputting this information filters results, displaying detailed exploded views showcasing belt routing and component placement.

These diagrams aren’t merely visual aids; they include corresponding part numbers, facilitating accurate replacement ordering. The system often provides multiple views, highlighting belt paths from different angles for clarity. Furthermore, MTD’s website frequently links to compatible Husqvarna diagrams, acknowledging the shared engineering and parts across certain models. Utilizing this online tool streamlines the process of understanding the belt configuration and ensures you’re referencing the correct diagram for your specific 46-inch deck MTD mower.

Husqvarna Parts Diagrams (Compatibility)

Given Husqvarna’s acquisition of MTD’s outdoor power equipment division, significant overlap exists in parts and diagrams, making Husqvarna’s resources highly valuable. Many MTD 46-inch deck models share components with Husqvarna Z4822 and Z4824 zero-turn mowers, meaning their parts diagrams can often be directly applied.

Accessing Husqvarna’s parts lookup tool, typically through their website, requires the model number. Even if your mower is branded MTD, searching with a compatible Husqvarna model (like those mentioned) can yield the correct belt diagram. This is particularly useful when MTD’s system lacks specific information for older or less common models. Cross-referencing part numbers is crucial; a belt listed for a Husqvarna 48-deck model (AYP/Husqvarna) may be identical to the one needed for your MTD 46-inch deck, simplifying the identification process.

Using Owner’s Manuals for Diagrams

The owner’s manual remains a primary source for locating the correct belt diagram for your MTD 46-inch deck mower. These manuals typically include exploded views illustrating the belt routing, identifying key components like spindles and idler pulleys. However, manuals can sometimes be incomplete or difficult to decipher, especially for older models.

If your original manual is missing, many manufacturers offer downloadable PDF versions on their websites. Searching using the mower’s model number is essential. The diagrams within often include detailed part numbers, aiding in accurate belt replacement. Remember that diagrams may vary slightly depending on the specific sub-model within the 46-inch deck range, so verifying compatibility is vital before ordering parts.

Decoding the Diagram

Successfully interpreting a manual MTD 46-inch deck belt diagram requires identifying spindles, idler pulleys, understanding belt routing, and tensioning systems.

Identifying Key Components (Spindles, Idler Pulleys)

Spindles are fundamental to the 46-inch MTD deck, housing the blade and bearing assembly, enabling blade rotation for cutting grass. Locating them on the diagram is essential; they’re typically positioned at each corner of the deck. Idler pulleys, conversely, guide the belt and provide tension, preventing slippage and ensuring efficient power transfer from the engine to the spindles.

On a manual diagram, idler pulleys appear as smaller wheels strategically placed along the belt’s path. Recognizing their position is vital for correct belt routing. The diagram will illustrate how the belt wraps around both the spindle pulleys and the idler pulleys. Correctly identifying these components is the first step towards understanding the belt’s path and performing successful replacements or adjustments. Misidentifying these parts can lead to improper installation and reduced cutting performance.

Understanding Belt Routing

Belt routing on an MTD 46-inch deck, as depicted in a manual diagram, is a precise sequence of loops and wraps around spindles and idler pulleys. The diagram visually demonstrates how the belt transmits power from the engine to each blade spindle, facilitating grass cutting. Typically, the belt begins at the engine pulley, travels to an idler pulley for tension, then loops around each spindle pulley in a specific order.

Following the diagram’s arrows is crucial; incorrect routing leads to belt slippage, reduced cutting efficiency, or even belt breakage. Note any belt guides or retainers shown on the diagram, as these ensure proper alignment. Understanding the routing pattern allows for accurate belt replacement and troubleshooting of drive system issues. A correctly routed belt is fundamental for optimal mower performance and longevity.

Recognizing Tensioning Systems

MTD 46-inch deck belt diagrams clearly illustrate the tensioning system, vital for maintaining proper belt tightness and preventing slippage. Most models employ an idler pulley, spring-loaded or manually adjustable, to apply tension to the belt. The diagram will show the idler’s position and how it interacts with the belt’s path.

Some systems utilize a fixed idler and rely on deck height adjustment for tensioning. Understanding the specific system is crucial during belt replacement; releasing tension correctly simplifies removal and installation. Diagrams often depict the adjustment mechanism – a lever, bolt, or spring – and its operational direction. Proper tension ensures efficient power transfer and prevents premature belt wear, contributing to the mower’s overall performance and reliability.

Replacing the Belt: Step-by-Step

Following a manual MTD 46-inch deck belt diagram, safely disconnect the spark plug, remove the deck, and carefully replace the worn belt for optimal function.

Safety Precautions Before Starting

Prior to any belt replacement utilizing a manual MTD 46-inch deck belt diagram, stringent safety measures are paramount. Always disconnect the spark plug wire and secure it away from the plug to prevent accidental starting.

Wear appropriate safety glasses and gloves to protect your eyes and hands from debris and sharp edges. Ensure the mower is on a level surface and the blades are cool to the touch.

If lifting the mower deck, use proper lifting techniques or a mechanical lift to avoid strain or injury. Never work under a mower supported only by a jack.

Be mindful of fuel and oil spills, cleaning them immediately.

Consult the owner’s manual for specific safety guidelines related to your MTD model.

Removing the Old Belt

Referring to your manual MTD 46-inch deck belt diagram, begin by locating the belt’s routing path around the spindles and pulleys. Carefully note the belt’s path for reinstallation.

Release tension from the belt by disengaging the tensioning system – typically an idler pulley. Use a wrench or socket to move the idler pulley, creating slack.

Once loosened, carefully remove the old belt from the pulleys, starting with the engine pulley and then the deck pulleys.

Inspect the pulleys for wear, damage, or debris. Clean or replace as needed.

Pay attention to any belt guides or retainers and note their positions for proper reassembly.

Installing the New Belt

With the old belt removed, consult your manual MTD 46-inch deck belt diagram to ensure correct routing of the new belt. Begin by positioning the new belt onto the engine pulley, ensuring it seats properly within the grooves.

Carefully route the belt around each spindle pulley, following the diagram precisely. Double-check that the belt is correctly aligned and not twisted or pinched.

Engage the tensioning system (idler pulley) to apply tension to the belt. Verify the belt is snug and properly seated on all pulleys.

Confirm the belt isn’t rubbing against any obstructions and that all belt guides are correctly positioned.

Finally, re-inspect the entire installation against the diagram before operation.

Troubleshooting Belt Issues

Referencing the manual MTD 46-inch deck belt diagram aids in diagnosing slippage, wear, or noise, pinpointing issues with spindles or tensioning systems.

Belt Slippage Causes and Solutions

Identifying the root cause of belt slippage on your MTD 46-inch deck, using the manual diagram, is paramount for effective repair. Common culprits include a worn or damaged belt, misaligned pulleys, or insufficient belt tension. A stretched belt, visually confirmed with the diagram as a reference, loses its grip.

Inspect pulleys for damage – cracks or excessive wear diminish their ability to maintain belt contact. The manual diagram helps locate all pulleys needing inspection. Insufficient tension, often due to a faulty idler pulley (again, diagram-assisted identification), prevents proper engagement.

Solutions involve replacing worn belts with the correct specification (refer to the diagram for part numbers), realigning pulleys, and adjusting belt tension. Regularly checking and maintaining proper tension, guided by the manual’s visual aid, prevents recurring slippage and extends belt life.

Premature Belt Wear – Identifying the Problem

Diagnosing premature belt wear on your MTD 46-inch deck requires a systematic approach, utilizing the manual’s belt diagram as a key reference point. Excessive wear isn’t always due to age; often, underlying issues accelerate degradation. Inspect the belt for cracking, fraying, or glazing – signs of stress or misalignment;

The diagram aids in pinpointing potential problem areas. Misaligned spindles or idler pulleys create friction, rapidly wearing the belt. Debris accumulation under the deck, though not directly shown on the diagram, contributes to abrasion. A worn spindle bearing, identifiable through noise and vibration, also induces belt stress.

Regularly check spindle and pulley alignment, referencing the manual’s diagram for correct positioning. Clean the deck thoroughly to remove debris. Addressing these issues proactively prevents frequent belt replacements and ensures optimal cutting performance.

Noisy Operation Related to the Belt

Unusual noises emanating from the deck during operation often signal a belt-related issue, and the manual’s diagram is invaluable for tracing the source. Squealing sounds frequently indicate belt slippage, potentially caused by a loose belt tension or worn pulleys. A flapping noise suggests a damaged or improperly routed belt, easily verified using the diagram.

The diagram helps visualize the belt’s path, allowing you to confirm correct installation. A worn or seized spindle bearing can also create noise, indirectly affecting belt performance. Inspect the idler pulleys for smooth rotation; a failing pulley generates a grinding sound.

Referencing the diagram, check belt tension and alignment. Replace worn pulleys or bearings promptly to prevent further damage and restore quiet operation. Ignoring these noises can lead to belt failure and more extensive repairs.

Related Parts and Maintenance

Maintaining spindles, idler pulleys, and the deck itself is vital for belt longevity, and the diagram aids in identifying these key components for upkeep.

Spindle Assembly Replacement

A worn spindle assembly significantly impacts belt performance and can lead to premature belt failure, as highlighted by online resources. When referencing a manual MTD 46-inch deck belt diagram, identifying the spindle assemblies is crucial for accurate replacement. The diagram will illustrate the spindle’s position relative to the belt routing and other deck components.

Replacement typically involves removing the cutting blade, then disconnecting the spindle from the deck. Ensure proper support during removal, as these assemblies can be heavy. Inspect the spindle shaft for damage or wear before installing the new assembly. Correct torque specifications, often found in the owner’s manual or parts diagrams, are essential for secure mounting and preventing future issues. Proper spindle function ensures even blade rotation and optimal cutting performance, directly impacting belt stress.

Idler Pulley Inspection and Replacement

The manual MTD 46-inch deck belt diagram clearly shows the idler pulleys’ role in maintaining proper belt tension, a critical factor for efficient operation. Regular inspection is vital; check for bearing wear, indicated by noise or stiffness when rotated. A seized or damaged idler pulley directly contributes to belt slippage and accelerated wear, as noted in various online repair guides.

Replacement usually involves removing the belt from the pulley, then unbolting the pulley from the deck; Ensure the new pulley is correctly aligned to prevent premature belt wear. Refer to the diagram to confirm correct positioning. Tighten mounting bolts to the manufacturer’s specified torque. A functioning idler pulley system ensures consistent belt tension, maximizing power transfer and extending belt life, ultimately improving cutting performance.

Deck Maintenance for Belt Longevity

Consistent deck maintenance, guided by the manual MTD 46-inch deck belt diagram, significantly extends belt life. Regularly cleaning the underside of the deck prevents grass buildup, which can cause excessive belt wear and strain on the spindles. Inspecting the deck for damage – bent metal or sharp edges – is crucial, as these can quickly shred a belt.

Maintaining a level deck ensures even cutting and reduces uneven stress on the belt system. Proper blade sharpening is also essential; dull blades force the engine to work harder, increasing belt load. Periodically check spindle bearings for play, as worn spindles contribute to misalignment and belt failure. Following these preventative measures, alongside referencing the diagram, maximizes belt performance and minimizes costly repairs.

Compatibility with Husqvarna Models

The manual MTD 46-inch deck belt diagram aids in verifying compatibility with Husqvarna Z4822 and Z4824 models, utilizing cross-referenced belt numbers.

Z4822 and Z4824 Compatibility

Understanding the compatibility between MTD 46-inch deck belt diagrams and Husqvarna Z4822/Z4824 models is vital for correct belt replacement. These Husqvarna zero-turn mowers frequently utilize belts interchangeable with those specified in MTD diagrams. Specifically, the 5/8 X 539109243 belt is often cited as compatible for the 48-inch deck found on these models.

However, always double-check the original equipment manufacturer (OEM) part number for your specific machine. Utilizing a manual MTD 46-inch deck belt diagram alongside Husqvarna parts lists ensures accurate identification. Cross-referencing part numbers like 754-04142 and 954-04142 (common MTD belts) with Husqvarna’s documentation is a best practice. Incorrect belt installation can lead to slippage, premature wear, and reduced cutting performance.

Cross-Reference of Belt Numbers

Accurate belt number cross-referencing is paramount when using a manual MTD 46-inch deck belt diagram for repairs. MTD frequently uses part numbers like 754-04142 and 954-04142 for 46-inch decks, but these may correspond to belts used in Husqvarna/AYP models as well. For instance, the 5/8 X 539109243 belt is often a suitable replacement for certain 48-inch Husqvarna decks.

However, direct substitution isn’t always guaranteed. Always verify compatibility using both the MTD diagram and the Husqvarna parts lookup tools. Online resources and owner’s manuals provide crucial cross-reference information. Utilizing these resources minimizes the risk of installing an incorrect belt, preventing slippage, damage to the deck, and ensuring optimal cutting performance. Careful verification saves time and money.

Understanding AYP/Husqvarna 48 Deck Models

AYP (American Yard Products) and Husqvarna often share components, impacting belt diagrams even for seemingly 46-inch MTD decks. Many Husqvarna Z4822 and Z4824 models utilize belts compatible with MTD 46-inch setups, creating potential cross-over scenarios. Understanding this relationship is vital when interpreting a manual MTD 46-inch deck belt diagram.

Specifically, designs for AYP/Husqvarna 48-deck models, like those referenced in parts lists (e.g., compatibility with part number 174356), can influence belt routing. While the deck size differs, the underlying mechanics are similar enough to warrant checking Husqvarna diagrams alongside MTD’s. This dual-check approach ensures accurate belt installation and prevents issues stemming from incorrect part selection or routing.