Single phase motor wiring diagram with capacitor start pdf provides detailed information on connections and capacitor usage in single phase motors for efficient operation and starting.

Overview of Single Phase Motors

Single phase motors are widely used in various applications due to their simplicity and cost-effectiveness. These motors operate on a single-phase AC power supply and are commonly used in residential and commercial appliances. The motor’s design and construction enable it to start and run using a single-phase power source. The use of capacitors in single-phase motors enhances their starting and running capabilities. Single phase motors are available in different types, including permanent split capacitor, capacitor start, and capacitor start-capacitor run motors. Each type has its unique characteristics and applications. The understanding of single phase motors is essential for designing and implementing effective wiring diagrams. By knowing the motor’s components and their functions, individuals can create accurate wiring diagrams for single phase motors with capacitor start, which is crucial for safe and efficient operation. This knowledge also helps in troubleshooting and maintenance of the motors.

Types of Single Phase Motors

Single phase motors include permanent split capacitor, capacitor start, and capacitor start-capacitor run types with distinct characteristics and applications in various fields and industries using different wiring diagrams.

Capacitor Start-and-Run Motor

A capacitor start-and-run motor is a type of single phase motor that uses a capacitor to start and run the motor. This type of motor is also known as a permanent split capacitor motor. The capacitor is connected in series with the start winding and remains in the circuit during operation. The capacitor start-and-run motor has a number of advantages, including high starting torque and efficient operation. The motor is suitable for applications where high starting torque is required, such as in compressors and pumps. The capacitor start-and-run motor is also relatively simple and inexpensive to manufacture, making it a popular choice for many applications. The motor’s performance can be adjusted by changing the value of the capacitor, allowing for flexibility in design and operation. Overall, the capacitor start-and-run motor is a reliable and efficient type of single phase motor. It is widely used in many industries.

Wiring Diagrams for Single-Phase Electric Motors

Single-phase electric motor wiring diagrams provide essential information on connections for safe operation and maintenance of motors.

Connection Diagram for Capacitor Start-Capacitor Run Motors

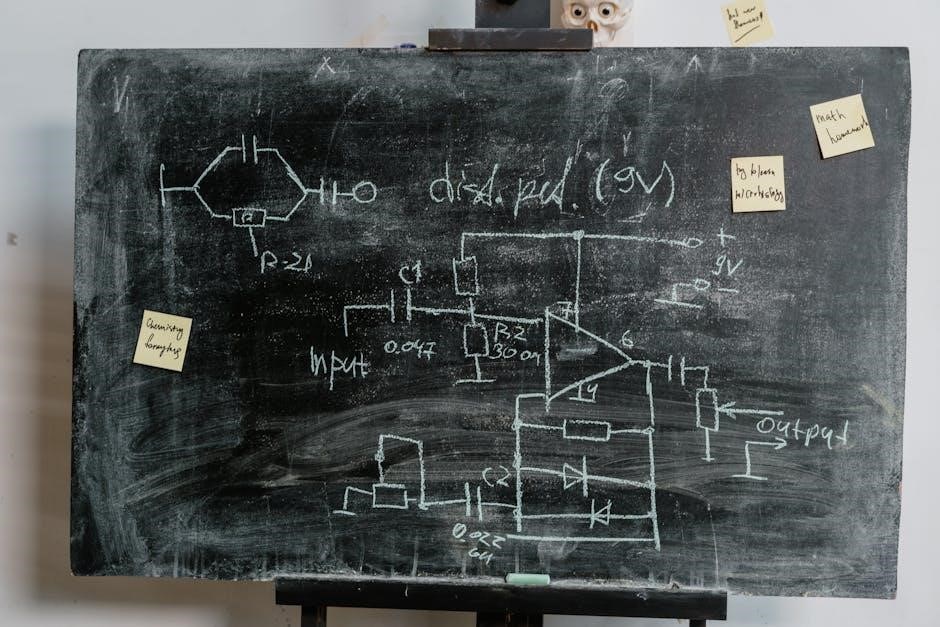

A connection diagram for capacitor start-capacitor run motors is crucial for understanding the wiring of these motors. The diagram typically includes the main winding, start winding, and capacitor connections. The capacitor is placed in series with the start winding, allowing for optimal torque delivery. The connection diagram also shows the terminal block and the wiring configuration for the motor. It is essential to follow the diagram carefully to ensure proper connection and safe operation of the motor. The diagram may also include information on changing the direction of rotation, which requires reconnecting the terminal block. A qualified electrician should perform this task to avoid any damage to the motor. The connection diagram is usually provided by the manufacturer and is specific to the motor model. It is an essential tool for installing, maintaining, and troubleshooting capacitor start-capacitor run motors.

Importance of Capacitor in Single Phase Motor

Capacitor plays a crucial role in single phase motor operation, enabling efficient starting and running, with optimal torque delivery and motor performance.

Role of Capacitor in Starting the Motor

The capacitor plays a vital role in starting the motor, as it provides the necessary voltage and current to initiate rotation. The capacitor is connected in series with the start winding, allowing it to deliver optimal torque. This configuration enables the motor to start efficiently, even under load. The capacitor’s role is to create a phase shift between the start and main windings, generating a rotating magnetic field that drives the motor. As the motor reaches its operating speed, the capacitor is typically disconnected from the circuit, allowing the motor to run efficiently. The capacitor’s size and type are critical in determining the motor’s starting performance, and its selection is based on factors such as the motor’s power rating and load characteristics. Proper capacitor selection is essential to ensure reliable and efficient motor operation. The capacitor’s role is crucial in single phase motor starting.

Single Phase Motor Connection Diagrams

Connection diagrams for single phase motors involve terminal blocks and wiring configurations for efficient operation.

Changing Direction of Rotation in Single Phase Motor

Changing the direction of rotation in a single phase motor involves modifying the wiring configuration. This requires reconnecting the terminal block, which should be done by a qualified electrician to avoid any damage or safety hazards. The process typically involves swapping the connections of the start and run windings, or reversing the polarity of the power supply. It is essential to follow the manufacturer’s instructions and guidelines for changing the direction of rotation, as incorrect wiring can lead to motor failure or other issues. Additionally, frequent stop/starts and changes in rotation direction can damage the motor’s capacitors and winding, reducing its lifespan and efficiency. Therefore, it is crucial to carefully plan and execute any changes to the motor’s rotation direction to ensure safe and reliable operation. This information is typically found in the motor’s documentation or wiring diagram.

Troubleshooting Single Phase Motor Wiring Diagrams

Troubleshooting involves identifying issues with the motor’s wiring and capacitors to ensure proper function and efficient operation of the single phase motor.

Common Issues with Capacitor Start Motors

Capacitor start motors are prone to various issues, including faulty capacitors, worn-out start windings, and incorrect wiring. These problems can lead to reduced motor performance, overheating, and premature failure. The capacitor is a critical component in the motor’s starting circuit, and its failure can prevent the motor from starting or running efficiently. Frequent stop/starts and changing the direction of rotation can also damage the motor’s capacitors and windings. To troubleshoot these issues, it is essential to refer to the motor’s wiring diagram and follow proper repair procedures. A qualified electrician should perform repairs to ensure the motor is properly wired and functioning correctly. Regular maintenance and inspection can help identify potential issues before they become major problems, reducing downtime and extending the motor’s lifespan. Proper installation and wiring are crucial to prevent common issues with capacitor start motors.